HEINZMANN Electric Drives

Robust electric motors

REGULATEURS EUROPA

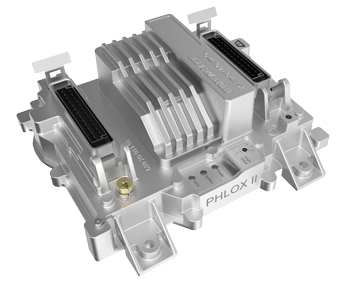

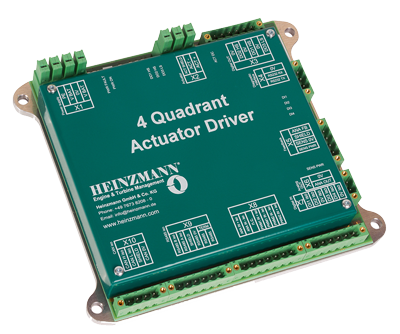

Control & Monitoring

HEINZMANN China

Control & Actuation

HEINZMANN Automation

Marine Automation

HEINZMANN UK

Gas & Water Turbine Control

HEINZMANN Australia

Steam Turbine Control

CPK Automotive

Emission Control

Giro Engineering

Diesel Engine Components

HEINZMANN IFT GmbH

Oil Mist Separators and Blow-by Filter Technology

HEINZMANN - Experts for marine applications

Our solutions have proven themselves in countless applications.

Do you have any questions? We will be happy to answer them!

Upgrade of Obsolete Woodward Actuators on Offshore Drilling Rig

By replacing obsolete Woodward actuators with Heinzmann’s advanced system, the rig owner restored full engine performance and reliability across all eight engines. This successful project underlines the importance of proactive upgrades and showcases Heinzmann’s ability to deliver effective engine control solutions in demanding offshore environments.

Icebreaker converted to Common Rail Injection

On a Swedish icebreaker, HEINZMANN succeeded in converting the propulsion engine of the ship from mechanical fuel injection to common rail injection.The customised solution is available for almost any four-stroke- or two-stroke engine and delivers outstanding results in terms of engine optimisation, fuel saving, noise behaviour and exhaust emissions, especially in terms of smoking behaviour.

Equipped with low-emission engines

HEINZMANN, one of the few manufacturers of classified gas engine controls in the world, has joined forces with engine specialist MAN Rollo B.V. and engine manufacturer MAN Engines to redefine the limits of what is technically feasible and shift the standards. By 2025, the innovative cooperation with MAN Engines and MAN Rollo will see 40 ships equipped with low-emission engines and put into service as part of the Parsival project.

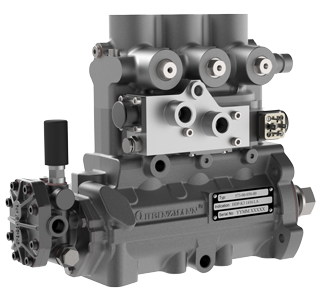

Seagoing Vessel Governor Replacement

The seagoing vessel ARM22 Klaas Adriana, a Dutch ocean-going vessel, is driven by a Caterpillar 3606 DI-TA engine. This engine is controlled by the 1100 series hydraulic governor from REGULATEURS EUROPA. The governor replaces the previously installed Woodward 3161 governor, which gave rise to increased maintenance costs and dysfunctions. The 1115L is a regulator widely used in the marine sector with an electric stepper motor as the actuator.

LNG powered Open Sea Ferry MS Helgoland

The gas powered open sea ferry from Cuxhaven to Helgoland is the first newly built seagoing ferry to be operated with liquefied natural gas. The main propulsion is a dual-fuel motor and is driven by 99 % liquid gas fuel and 1 % diesel.

The LNG generator sets for on-board power generation by MAN Rollo B.V. are regulated through an engine management and monitoring system by HEINZMANN.