To ensure that combustion engines operate very efficiently, turbocharging is absolutely essential to improve the power output and the engine’s efficiency. For this reason, sophisticated control elements are required on the side of the hot engine exhaust gases in particular, in order to precisely and reliably control the boost pressure. HEINZMANN can provide this equipment, which includes all components required to control the wastegate.

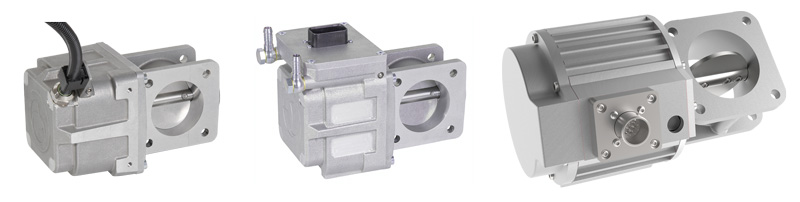

Wastegate Valves

Flat Housing

Housing with flange

Cone Housing

Wastegate Valves

The wastegate throttle valves are used to control turbocharged engines. The throttle valve determines the amount of exhaust gas driving the turbocharger’s turbine. This is because the load depends on the torque of the compressor wheel, which is connected to the turbine via a shaft. When closed, the throttle valve stops ensure a better seal and minimal leaks. This arrangement means that the blocking cannot occur in the closed position.

- Resistant to high temperatures and corrosion

- Optimal sliding properties over a wide temperature range

- Connection to the actuator can be established using a linkage or a shaft with a high-temperature coupling

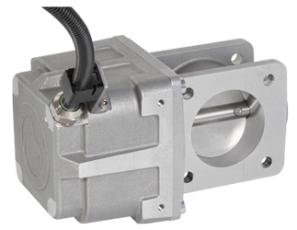

Flat housing

Technical data

- Diameter: 30, 40, 50, 60, 66, 70, 90 mm

- Operating temperature: -40 ... +550 °C; up to +750 °C on request

- Max. differential pressure: 5 bar abs.

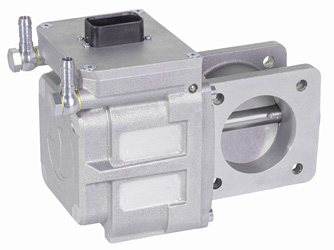

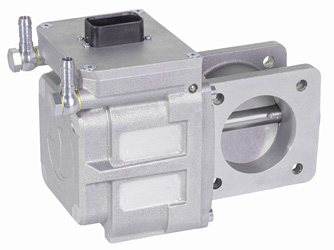

Housing with flange

Technical data

- Diameter: 120, 170, 200 mm

- Operating temperature: -40 ... +550 °C; up to +750 °C on request

- Max. delta pressure: 5 bar abs.

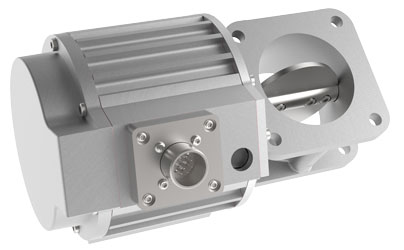

Cone housing

Cone housing

Technical data

- Diameter: 30, 40, 50, 60, 70 mm

- Operating temperature: -40 ... +550 °C; up to +750 °C on request

- Max. delta pressure: 5 bar abs.

Turbocharger Bypass

DK 100 / StG 3

DK 140 / StG 2080-PD

DK 100/StG 3-PD | DK 100/StG 3+-PD

DK 200/StG 3-PD | DK 200/StG 3+-PD

Turbocharger Bypass

Turbocharger bypass throttle valves have been specifically optimised for this field. They have been specially designed to withstand the higher differential pressures that occur in this application. The turbocharger bypass valves are also available with a return spring that acts in the other direction.

- Fast response

- No maintenance required

DK 100 / StG 3

Throttle Valve with Actuator

Technical data

- Output range stoichiometric: 70 ... 250 kW

- Steady state torque: approx. 1.5 Nm

- Ø Throttle valve: 48 | 60 | 68 mm

- Boost pressure at valve: max. 5.8 bar abs.

- Response time: less than 40 ms

DK 140 / StG 2080-PD

Throttle Valve with Positioner

Technical data

- Voltage supply: 18 … 33 VDC

- Ambient tempertaure: -25 … +90 °C

- Ø Throttle valve: 85 mm

- Boost pressure at valve: max. 8 bar (abs.)

- Response time: 90 ms

DK 100/StG 3-PD | DK 100/StG 3+-PD

Throttle Valve with Positioner

Technical data

- Voltage supply: 18 ... 32 VDC, nom. 24 VDC

- Operating temperature range: -20 ... +100 °C

- Ø Throttle valve: 48 / 60 / 68 mm

- Boost pressure at valve: max. 5.8 bar abs.

- Response time: less than 40 ms

DK 200/StG 3-PD | DK 200/StG 3+-PD

Throttle Valve with Positioner

Technical data

- Voltage supply: 18 ... 32 VDC, nom. 24 VDC

- Operating temperature range: -20 ... +100 °C

- Ø Throttle valve: 80 / 90 / 100 / 110 mm

- Boost pressure at valve: max. 4 bar abs.

- Response time: less than 40 ms