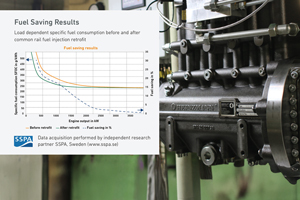

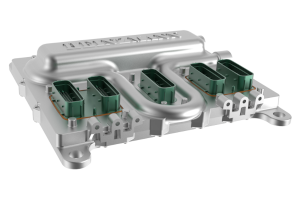

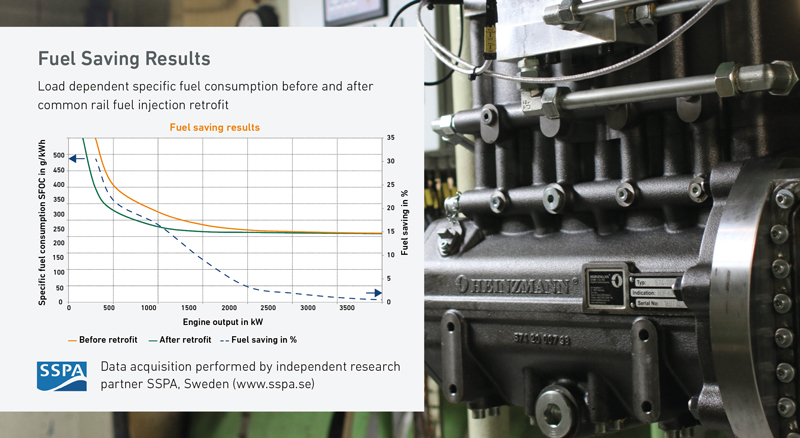

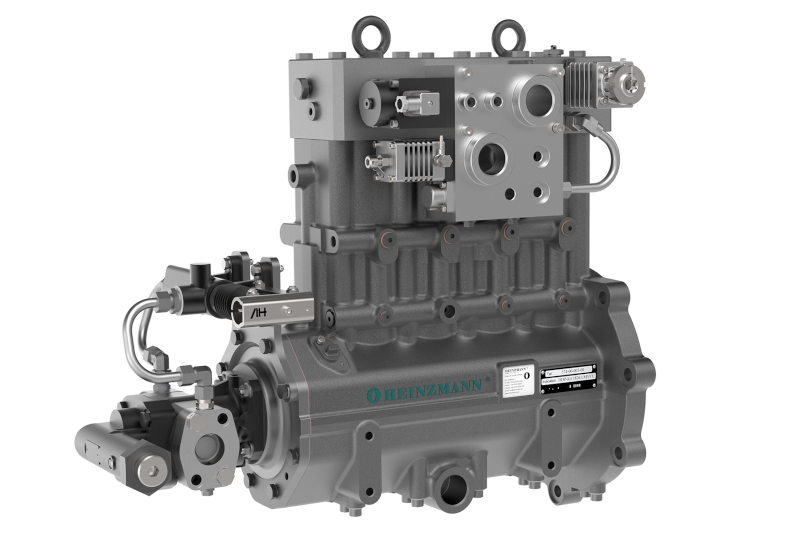

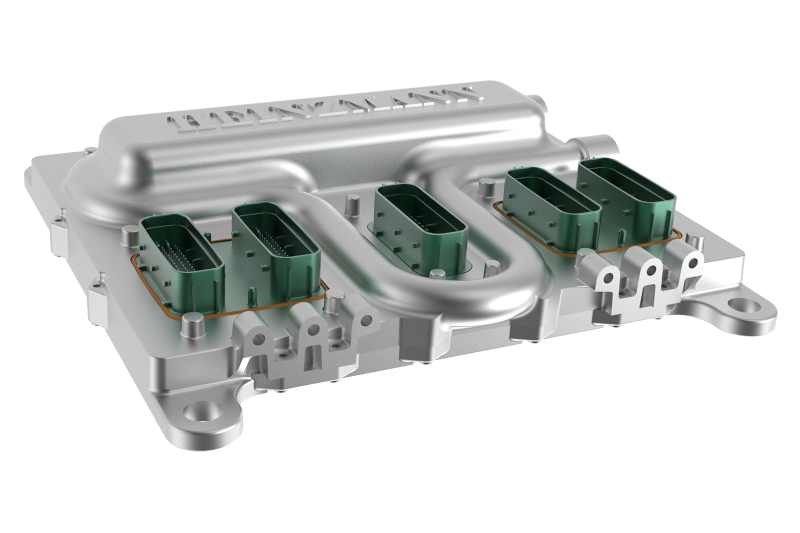

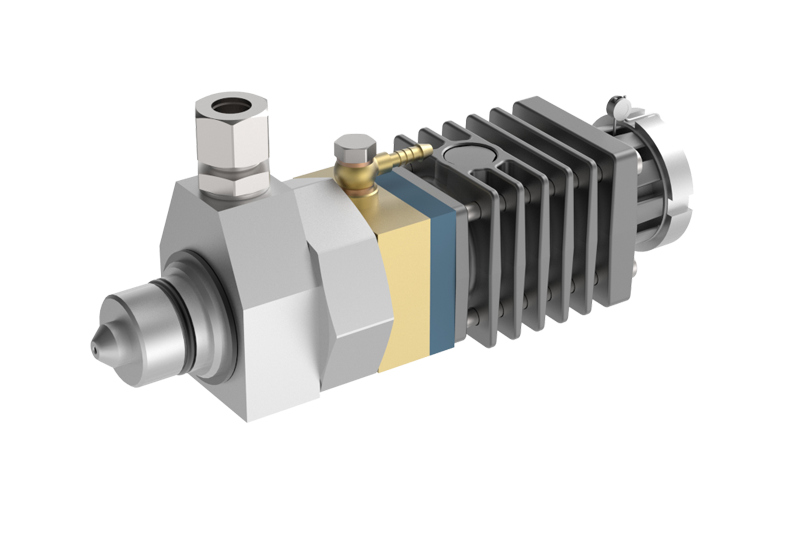

Conversion to common rail is particularly recommended for all applications with variable loads and speeds, as this enables all the advantages of electronic fuel injection to be exploited. Due to the considerable reduction in fuel that can be achieved, the investment can pay for itself in less than two years (at >5000 operating hours per year). Complete common rail solutions, including monitoring and protection systems, along with touch screen based operating units, are supplied from a single source. HEINZMANN offers comprehensive services for these products, including feasibility studies, engineering, installation, commissioning and maintenance. Engine sizes range from 500 kW to over 10,000 kW.

Common Rail Retrofit

DEVELOPMENT PARTNER

HEINZMANN has a high reputation as a development partner. Our engineers will work with you to find a customised solution for your retrofit.

- Examination of the possibilities and chances of success of retrofitting

- Concept development based on manufacturer information

- Measurement of the motors and clarification of the installation conditions

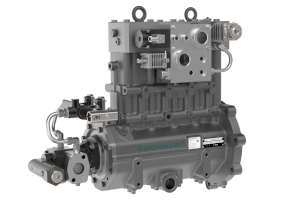

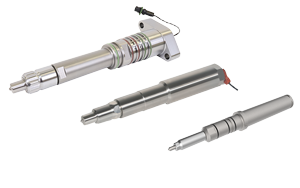

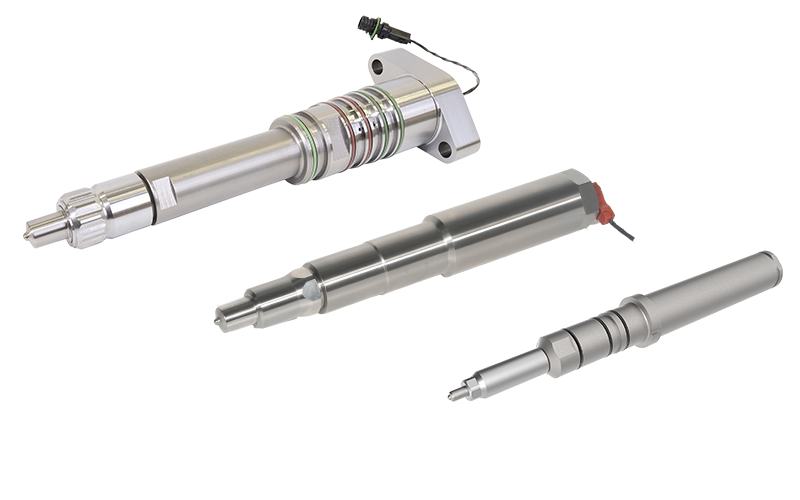

- Design and manufacture of the system components with the necessary adaptations

- Installation of the common rail system

- Commissioning the engine

- Customer training and comprehensive documentation of the conversion

- Evaluation of the remodelling measures

In-house production

- Sustainable, environmentally friendly and energy-saving production processes in all production steps

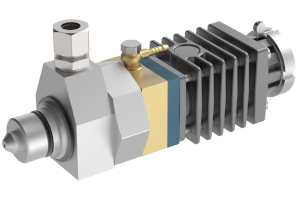

- Modern machinery for high-precision production of injection system components

- Production at HEINZMANN guarantees the highest quality of all components

- State-of-the-art measuring and testing equipment to verify the required precision

Worldwide service

Our highly qualified service team guarantees the best possible customer support during installation, commissioning and system set-up.

- Comprehensive on-site service. We travel to our customers wherever they are located

- Short response times are a given

- HEINZMANN has a large worldwide network of authorised service partners

- Our service engineers are experts in HEINZMANN products and take care of parts procurement, installation, repair and maintenance

- Short downtimes thanks to the installation of spare parts stored on site