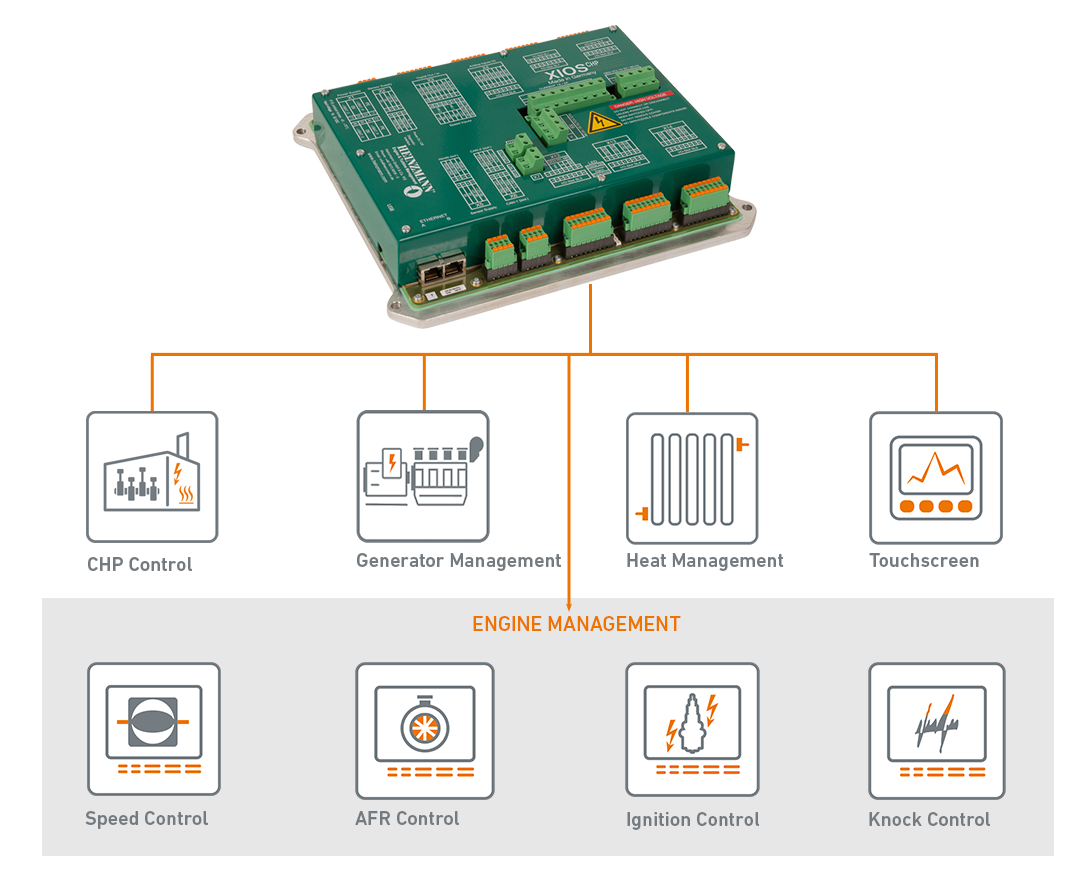

As a long established system supplier of engine management solutions for combustion engines in the industrial field, HEINZMANN has a range of reliable controllers which are widely successful in different applications from power generation to marine propulsion. The newly developed and extensively tested CHP control unit for gas engines combines all the benefits of the HEINZMANN control systems into a compact, integrated solution. This provides reliable usage for heat and electricity power whether in mainsparallel or island operation.

Full control of the CHP system with XIOSCHP

Engine, generator, CHP and heat management as well as various monitoring functions are integrated in one central control unit, XIOSCHP. With many configurable I/Os, various kinds of communication protocols and user-friendly HMI touch-screens, XIOSCHP provides the customer full control of the CHP system with minimum effort.

CHP Management

- CHP selectively heat or load-driven

- Gas train control

- Engine start/stop sequence

- Oil level control

- pre-heat functions & room ventilation

- Remote access via VPN

Genset Management

- Applications: Island/grid/peak shaving/base load

- Automatic synchronisation and load control

- Voltage/cosPhi control via bias signal to AVR

- Dynamic load adjustment at frequency fluctuations

- Power Management

Heat Management

- Up to 4 independent configurable PID governors for heat circuitsr

- Pre-heating by control of a heating rod

- Coolant circuits temperature/pressure monitoring

- Monitoring of coolant temperature difference

- Engine and intercooler coolant temperature control

Touch Screen

- Easy handling

- Icon based intuitive interface

- 7‘‘ to 15‘‘ display, either capacitive or resistive

- Permanent navigation bar including date, time and major icons

- Password protected access levels

- Customised system overview/main screen possible

- Industrial and robust design

Speed Control

- Integrated speed control

- Fast reaction on speed and load changes

- Combination with all HEINZMANN actuators possible

AFR Control

- Power, lambda or NOx feedback

- Specific control solutions for different gas qualities

Ignition Control

- Speed and load dependent ignition timing

- Autospark function to reduce spark plug wear

Knock Control

- Monitoring of knocking combustion

- Ignition angle correction and load reduction

-

CHP Management

- CHP selectively heat or load-driven

- Gas train control

- Engine start/stop sequence

- Oil level control

- pre-heat functions & room ventilation

- Remote access via VPN

-

Genset Management

- Applications: Island/grid/peak shaving/base load

- Automatic synchronisation and load control

- Voltage/cosPhi control via bias signal to AVR

- Dynamic load adjustment at frequency fluctuations

- Power Management

-

Heat Management

- Up to 4 independent configurable PID governors for heat circuitsr

- Pre-heating by control of a heating rod

- Coolant circuits temperature/pressure monitoring

- Monitoring of coolant temperature difference

- Engine and intercooler coolant temperature control

-

Touch Screen

- Easy handling

- Icon based intuitive interface

- 7‘‘ to 15‘‘ display, either capacitive or resistive

- Permanent navigation bar including date, time and major icons

- Password protected access levels

- Customised system overview/main screen possible

- Industrial and robust design

-

Speed Control

- Integrated speed control

- Fast reaction on speed and load changes

- Combination with all HEINZMANN actuators possible

-

AFR Control

- Power, lambda or NOx feedback

- Specific control solutions for different gas qualities

-

Ignition Control

- Speed and load dependent ignition timing

- Autospark function to reduce spark plug wear

-

Knock Control

- Monitoring of knocking combustion

- Ignition angle correction and load reduction