HEINZMANN Electric Drives

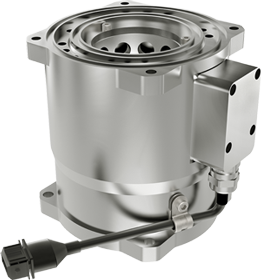

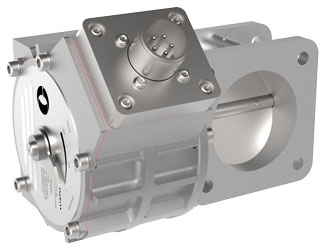

Robust electric motors

REGULATEURS EUROPA

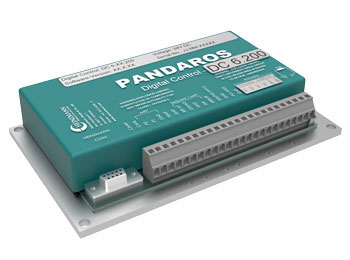

Control & Monitoring

HEINZMANN China

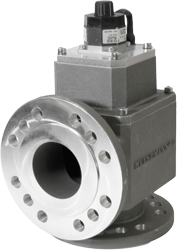

Control & Actuation

HEINZMANN Automation

Marine Automation

HEINZMANN UK

Gas & Water Turbine Control

HEINZMANN Australia

Steam Turbine Control

CPK Automotive

Emission Control

Giro Engineering

Diesel Engine Components

HEINZMANN IFT GmbH

Oil Mist Separators and Blow-by Filter Technology

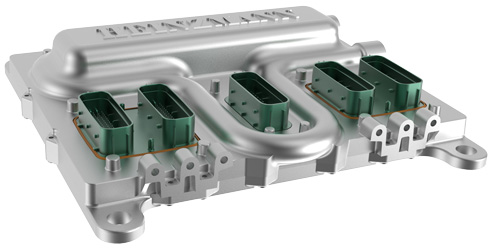

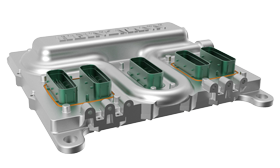

Optimal control technology for any type of dual-fuel engine

Retrofit to Dual-Fuel Operation for Fred Olsen High-Speed Vessel

Test bench runs on a CATERPILLAR 3618 engine have recently been successfully completed for the world’s first dual-fuel conversion on a marine high-speed propulsion engine. The project was initiated by Norwegian shipping line Fred. Olsen S.A. who chose HEINZMANN as a competent and innovative supplier of dual-fuel systems.

Dual-Fuel-System for Caterpillar 3516

In co-operation with the Dutch company PonPower, HEINZMANN converted the diesel engines of the demonstration ship Argonon to dual-fuel operation. As a result of the conversion, diesel injection is now only 20 %. In addition to considerable cost savings, HEINZMANN has reduced the ship's emissions and pollution.

Dual-Fuel for Navy GenSet

Anglo Belgian Corporation (ABC) has equipped the new TESO ferry between Texel and Den Helder with two diesel and two dual fuel motors. There are two ABC 12VDZD and two ABC 12 VDZ motors, which are controlled by a HEINZMANN system. The ABC motors have a speed of 1000 rpm and an electrical output of 2000 kW.

SDMO Industries S. A. converts to dual-fuel operation

HEINZMANN supplied SDMO Industries S.A., a French manufacturer of gensets, with the ARTEMIS dual-fuel system. With the HEINZMANN system, the Mitsubishi diesel engine used by SDMO Industries S.A. for its generator set was successfully converted to dual-fuel operation.

Dillingen municipal utilities convert to dual-fuel operation

Since subsidies for palm oil were cancelled by the German government and the operation of diesel engines with palm oil is no longer profitable, generator sets are increasingly being converted to natural gas or biogas. The municipal energy supplier from Dillingen an der Donau has converted to dual-fuel with the support of HEINZMANN.

Dual-Fuel-System for Hummel Energie Holding GmbH

HEINZMANN was given the commission of changing over a motor of Hummel Energie Holding GmbH to dual-fuel operation. Due to the installation of the dual-fuel system ARTEMIS, the goal of fuel cost savings and emission reductions were successfully achieved.

HEINZMANN Dual-Fuel-System for Mitsubishi Motor

In collaboration with HEINZMANN, the company Kraft Power Corporation, based in Ohio, USA, carried out the changeover of its diesel motor Mitsubishi SR6 to dual-fuel operation. After delivery and installation of the dual-fuel system ARTEMIS, the project was successfully completed, thereby achieving fuel savings and a reduction of emissions.

Dual Fuel System for Völkl Motorentechnik GmbH

HEINZMANN has supported Völkl Motoren Technik GmbH to change over the company's MAN diesel motor to dual-fuel operation. The main objectives were fuel savings and emission reductions. The project was successfully completed by delivery and installation of the dual-fuel system ARTEMIS.