- Bo-Bo-Locomotive

- CountryLink

- TEM-2

- TEM-7

- HXN3B

- ChME-3 6221 and 6831

Bo-Bo-Locomotive

Systems and components

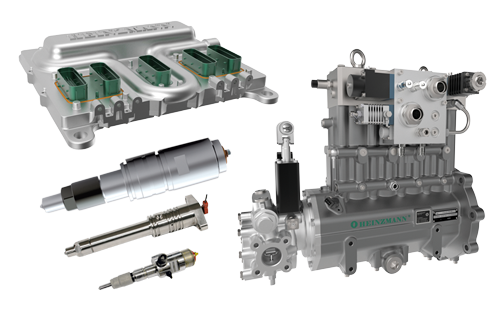

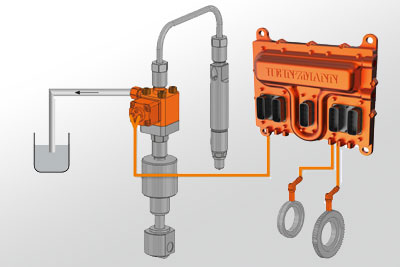

- ODYSSEUS Common Rail Injection System

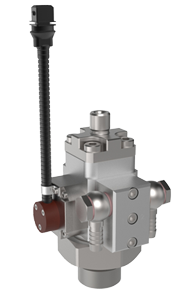

- HDP-K3 High-pressure pump

- MVC 01-20 EFI control

- ICR-DS-200 Injector

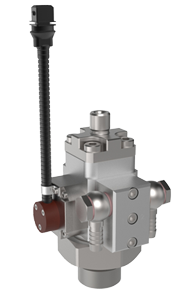

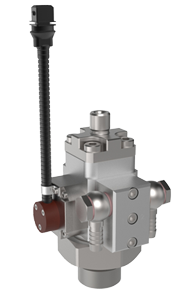

- RPLV-2S Rail Pressure Limiting Valve

- DcDesk 2000

- PEGASOS Control System

HEINZMANN Common Rail System on GM185V-VG-CR

HEINZMANN has successfully completed the dressing of a GM185V-VG-CR diesel engine for locomotives with a common rail fuel injection system. The target to fulfil the emission standard Stage IIIA according to Directive 97/68 EC was met by applying the following components: a high-pressure pump, magnetic valve control and injectors for a prechamber injection. With an additional diesel particulate filter, the engine now fulfils even Stage IIIB.

The GM185V-VG-CR engine family of the Hungarian engine manufacturer Ganz Motor Kft., located in Budapest, is the reengineered version of the S.E.M.T. Pielstick PA4V 185VG engine family. These are typical high-speed diesel engines that offer a wide power range depending on the number of cylinders. They are produced on a worldwide scale by license and are used mainly in railway applications.

CountryLink

Systems and components

- RE Viking35 Traction Control Panel

Viking35 on High-Speed Trains

CountryLinks are the high-speed passenger trains which travel along the west coast of Australia. 3 of the existing power cars originally equipped with the reliable and long serving Viking22 traction control panels have been successfully upgraded to the latest Viking35 from REGULATEURS EUROPA (RE).

The control panel communicates seamlessly with the power car load control system as well as the originally supplied ENGMON engine monitoring system which automatically records and communicates any engine related alarms back to the train operator’s engineers.

TEM-2

Systems and components

- LAVINIA E-PPN Injection Control Valve

- EFI Control MVC 01-20

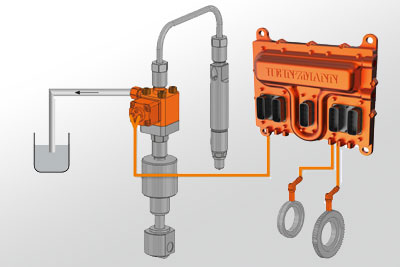

EFI Retrofit on Penzadieselmash D50 Engine

HEINZMANN has successfully finished the conversion of Ukrainian TEM2 locomotive in field use from conventional to electronic fuel injection control.

The electronically actuated E-PPN Injection Control Valves were used instead of the hydraulic-mechanical speed governor of the Penza D50 combustion engine: 6 cylinders in line, 620 kW at 750 rpm, turbocharged. By means of HEINZMANN's turnkey solution, fuel consumption of the locomotive was reduced by over 14 % and operating characteristics as well as maintenance requirements were improved.

At the heart of the PLN extension kit is the electronically actuated LAVINIA E-PPN Injection Control Valve which provides new qualities to conventional mechanical fuel injection systems (PLN). Together with the high-performance MVC 01-20 controller it optimises the combustion process in a map-controlled approach. Smooth engine running, reduced engine loads and improved emissions behavior are achieved via balanced injection quantities across all cylinders.

TEM-7

Systems and components

- LAVINIA E-PPN Injection Control Valve

- EFI control unit MVC 01-20

EFI Retrofit on Kolomna D49 Engine

HEINZMANN has successfully finished the conversion of a Russian TEM-7 locomotive in field use from conventional to electronic fuel injection control.

The electronically actuated E-PPN Injection Control Valve was used to supplement the mechanical fuel injection system of the Kolomna D49 combustion engine. By means of HEINZMANN's turnkey solution, fuel consumption of the locomotive was reduced by over 10 % and operating characteristics as well as maintenance requirements were improved.

It provides new qualities to conventional mechanical fuel injection systems (PLN). Together with the high-performance MVC 01-20 controller it optimises the combustion process in a map-controlled approach. Smooth engine running, reduced engine loads and improved emissions behaviour are achieved via balanced injection quantities across all cylinders.

HXN3B

Systems and components

- DARDANOS EFI Control MVC 01-20

Conversion to Solenoid Valve Injection of HXN3B Locomotives

HEINZMANN China has equipped a series of HXN3B locomotives, which are widely used as traction machines in China.

Via two CAN ports, the installed MVC 01-20 control system is used as an interface to the locomotive system and for signal processing with regard to external modules. In this context, the MVC 01-20 also acts as a monitoring system for engine monitoring. The high-quality system therefore contributes to the operational reliability and increased service life of the locomotives.

ChME-3 6221 and 6831

Systems and components

- LAVINIA E-PPN Valves

- EFI Control MVC 01-20

- Control Cabinet PEGASOS

- Display Unit ARGOS

- Speed Sensors

- Sensors for Exhaust Gas Temperature

E-PPN Retrofit at Locomotives ChME-3 6221 and 6831

In Ukraine, the installation of a locomotive control system with EPPN valves was carried out on locomotives ChME-3 with serial numbers 6221 and 6831. The commissioning of the locomotive control systems was carried out according to the contract with the company "UkrTransDiesel".

The locomotive control system with EPPN valves was installed on ChME-3 after overhaul of the locomotives. Tests and adjustment of both locomotives were carried out on a rheostat system.

Both locomotives are equipped with in-line diesel engines of the series K6S310DR (Praha). Number of cylinders: 6 cyl; engine power: 993 kW at 750 rpm; engine power per cylinder: 165.5 kW/cylinder.