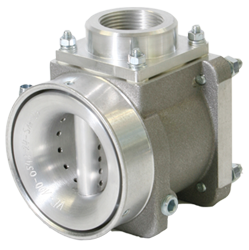

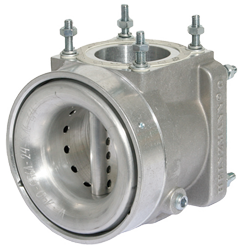

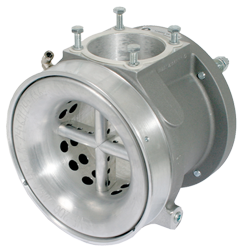

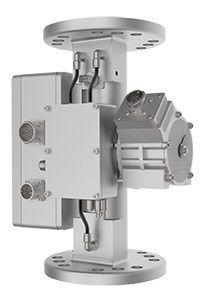

The KRONOS 30 is an electronically controlled mixture control system for adjusting speed-dependent and load-dependent lambda values in order to achieve ideal engine behaviour under all operating conditions. The flexible concept can be used to control engines with greater fluctuations in gas, engine and ambient parameters. The gas mixer configuration is independent of the application and enables operation with a large number of gases, including lean gases. The system has outstanding control accuracy, thus ensuring compliance with emission limits even under difficult conditions. The main applications are biogas and lean gas engines, which are supplied by blowers with slightly increased gas pressure.

For system configuration please provide application specific information: Order Information.