ARTEMIS dual-fuel systems are based on tried-and-tested components from gas engines and powerful actuators and control units from HEINZMANN. The cylinder-specific version based on a gas injection valve consists of an EFI control system, gas injection valves, and pressure and temperature sensors. The single-port injection concept achieves the best possible load behaviour whilst also minimising the risk of gas loss or backfires caused by valve overlaps. Designed for engines up to 1 MW, ARTEMIS systems are particularly well-suited to dual-fuel conversions on medium and fast-running diesel engines.

- MVC 01-24

- Software

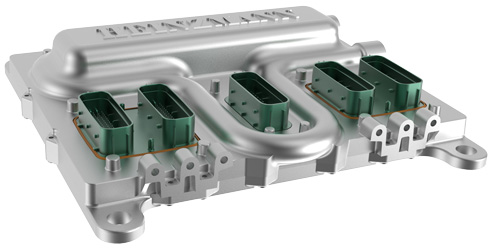

MVC 01-24

A solenoid valve control system for industrial diesel, gas and dual-fuel engines with a maximum of 24 cylinders. Enables up to seven precise injections per cylinder and stroke; large number of I/Os enables optimum engine operation and monitoring; can be used with any control system based on solenoid valves; combined with MEGASOL injection valves for gas injection systems. What’s more, up to 3 actuators can be actuated directly, for instance to control the air volume (throttle valve, turbocharger bypass, wastegates). It can be expanded as a redundant system for use in ship engines.

Technical data

- Power supply: 15 - 33 VDC (nom. 24 VDC)

- Injection boost current max./hold: max. 30 A / 18 A

- Ambient temperature: -40 ... 80 °C / -40 ... 125 °C with cooling

- Permissible ambient humidity: 95 % at 55 °C

- Vibration: 10-24 Hz 2 mm / 25-64 Hz 0,24 m/s / 65-2000 Hz 9 g

- Shock level: 30 g 11 ms - half sine wave

- EMC: EN 61000-4-2/-3/-4/-6

- Degree of protection: IP6K9K

- Weight: approx. 8.5 kg

Engine Types & Applications

![]() Diesel Engines

Diesel Engines

![]() Gas Engines

Gas Engines

![]() Dual-Fuel Engines

Dual-Fuel Engines

![]() Ships

Ships

![]() Locomotives

Locomotives

![]() Industrial Vehicles

Industrial Vehicles

![]() Gensets

Gensets

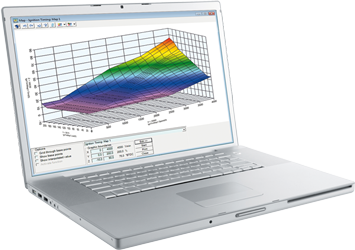

Software

The DcDesk software is a configuration and visualisation tool for all digital HEINZMANN systems. It comes with all functions for commissioning, monitoring and maintenance/diagnosis.

- MEGASOL Overview

- MEGASOL 60 II

- MEGASOL 200 II

- MEGASOL 250 II

- MEGASOL 400 II

- MEGASOL 425 II

- MEGASOL 1000

- MEGASOL Marine

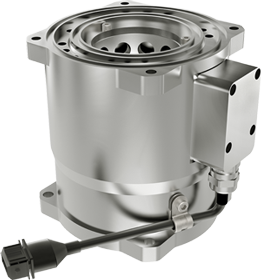

MEGASOL Gas Admission Valves

MEGASOL valves are designed to operate with a comparatively high differential pressure of supplying air and gas. They are characterized by excellent load response, precise dosage and individual adjustment of gas quantity for each cylinder. MEGASOL valves have a very low leakage when closed and are easy maintain.

- Precise metering of gas quantity for each cylinder individually

- Fast response and excellent load behaviour of engine

- Suitable for new engines as well as for retrofit solutions

- No risk of backfires

MEGASOL 60 II

Technical data

- Flow rate (Z-value): 17

- Max pressure gas supply: 8 bar | 116 psi

- Max. pressure air supply: 6 bar | 87 psi

- Max differential pressure: less than 3 bar | 43 psi

- Voltage supply: 90 VDC

MEGASOL 200 II

Technical data

- Power range: approx. 60 ... 300 kW/cylinder

- Flow rate (Z-value): 55

- Max pressure gas supply: 8 bar | 116 psi

- Max. pressure air supply: 6 bar | 87 psi

- Max differential pressure: less than 3 bar | 43 psi

- Voltage supply: 90 VDC

MEGASOL 250 II

Technical data

- Power range: about 60 ... 300 kW/cylinder

- Flow rate (Z-value): 69

- Max. pressure gas supply: 8 bar | 116 psi

- Max. pressure air supply: 6 bar | 87 psi

- Max. differential pressure: less than 3 bar | 43 psi

- Voltage supply: 90 VDC

MEGASOL 400 II

Technical data

- Power range: about 250 ...600 kW/cylinder

- Flow rate (Z-value): 105

- Max. pressure gas supply: 8 bar | 116 psi

- Max. pressure air supply: 6 bar | 87 psi

- Max. differential pressure: less than 3 bar | 43 psi

- Voltage supply: 90 or 24 VDC

MEGASOL 425 II

Technical data

- Power range: about 250 - 600 kW / cylinder

- Flow rate (Z-value): 128

- Max. pressure gas supply: 8 bar

- Max. pressure air supply: 6 bar

- Max. differential pressure: 3 bar

- Voltage supply: 90 VDC

MEGASOL 1000

Technical data

- Power range: about 500 ... 2000 kW/cylinder

- Flow rate (Z-value): 250

- Max. pressure gas supply: 8.5 bar

- Max. pressure air supply: 6.5 bar

- Max. differential pressure: 2.5 bar

- Voltage supply: 48 ... 110 VDC

More information

MEGASOL Marine

For marine applications the MEGASOL 200 II - 425 II are also available in marine versions.

Technical data

- Power range: 60 ... 300 kW/cylinder respectively 250 .. 600 kW/cylinder

- Flow rate (Z-value): 55 / 69 / 105 / 128

- Max. pressure gas supply: 8 bar

- Max. pressure air supply: 6 bar

- Max. differential pressure: 3 bar

- Voltage supply: 48 ... 110 VDC

- Overview Sensors

- Temperature sensors

- Pressure sensors

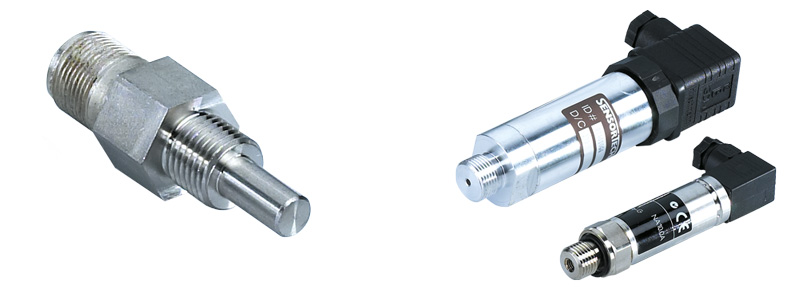

Sensors for Dual-Fuel Management

The ARTEMIS system also contains sensors for monitoring the pressure and temperature (gas, air, coolant, exhaust gases).

Temperature sensors

HEINZMANN high-quality temperature sensors based on Pt 100, Pt 200 or Pt 1000 measuring cells are used on all HEINZMANN systems and have become the industry bench mark for response times, long-term stability and measurement precision. The sensors are suitable for measuring fluids and gases and have degree of protection IP65.

Technical data

- Degree of protection: IP65

- Types and measuring ranges:

- Pt 100: -40... +800° / short-term +900 °C

- Pt 200: -40 ... +800 °C / short-term +900 °C

- Pt 1000: -40 ... +150 °C

Pressure sensors

HEINZMANN offers gas, boost and oil pressure sensors tailored to virtually any specification. The pressure sensors are renowned for their accuracy and reliability and guarantee precision pressure sensing.

Technical data

- Degree of protection: IP65

- Pressure range: 0 to 2.5, 4, 10, 16 up to 2000 bar

- Knock Control

Knock Control

The ARIADNE control unit is able to individually detect knocking combustion on each cylinder (max. 20) and maintain optimum operation under all conditions so as to protect the engine from damage.

Technical data

- Power supply: 18 ... 32 VDC

- Capacity: up to 20 knock sensor inputs

- Communication: 2x CAN bus, 1x Modbus, 1x serial interface

Engine Types & Applications

![]() Gas Engines

Gas Engines

![]() Dual-Fuel Engines

Dual-Fuel Engines

![]() CHP

CHP

![]() Gensets

Gensets