May 2025

HEINZMANN unveils modular low-pressure methanol PFI Injector platform – a fast-track decarbonisation solution for OEM engine builders

Zurich, May 2025 – At this year’s CIMAC Congress, HEINZMANN presented a production-ready methanol Port-Fuel-Injection (PFI) system for medium-speed engines. This was detailed in Technical Paper #253, ‘Further development of a methanol port fuel injection platform for medium-speed engines’. The new platform offers access to dual-fuel operation with methanol in simple low-pressure mode and diesel. These capabilities allow original equipment manufacturer (OEM) customers to easily transition to clean methanol combustion in newly built engines, as well as in retrofit solutions.

Lowering CAPEX and integration barriers

Conventional methanol-conversion programmes often stall because they require high-pressure pumps, boosters and intensifiers which drive up both capital expenditure (CAPEX) and the effort required for integration.

HEINZMANN’s new port-fuel injector overcomes this hurdle by producing a finely atomised spray at fuel pressures as low as 5–20 bar. This eliminates the need for costly high-pressure components without compromising performance targets.

The same core injector is designed to span several engine families, with advantageous combinations of nozzle diameters and deflector geometries expected to cover 100–500 kW per cylinder. This gives designers the potential to work with a uniform parts kit for multiple power ratings.

Thanks to the modular design comprising nozzle/deflector, flange and body, installation interfaces and fuel supply can be adapted with minimal effort. This accelerates prototype loops and reduces the risk of later modifications.

Embedded safety and marine-grade durability

Operational safety can be embedded too. An integrated flow-limiter valve restricts fuel delivery preventing over-injection in the event of a malfunction, such as an injector stuck open, thereby avoiding uncontrolled fuel injection.

Optionally, the double-walled design and materials proven in methanol applications provide additional reliability and facilitate class approval. This gives engine manufacturers quick and cost-effective access to using methanol as a fuel in low-pressure applications – with full control over total costs.

Key technical features at a glance

• Low-Pressure Operating Window – fine atomized spray at < 25 bar fuel pressure; no high-pressure components required

• Modular, Flexible Platform – Customisable flange, body, nozzle and patented deflector enable rapid tailoring for different performance ranges or installation spaces

• Optimised Spray Geometry – CFD-derived cone angles create a fine, uniform cloud (> 10.000 mm³/shot) for stable combustion and very low emissions

• Double-Wall Optionh – Double-walled design possible – in accordance with the selected safety concept

• Built-In Flow Limiter restricts fuel delivery — preventing over-injection and protecting engine in the event of a malfunction, such as an injector stuck open

• Corrosion-Resistant Materials – Proven alloys avoid high-cost materials and keep total cost of ownership low

• Ideally suited for retrofitting existing engines — simple integration without complex adjustments

The HEINZMANN Perspective

“Decarbonisation should not come at the expense of costly hardware or complex integration. Our new PFI injector platform provides an affordable way to start using methanol technology, which is exactly what a highly competitive industry needs. At the same time, it enables engine manufacturers to bring regulatory-compliant products to market more quickly”, says Markus Gromer, HEINZMANN's CEO.

Series launch is already under way with selected OEM partners.

Further information under Methanol Injector.

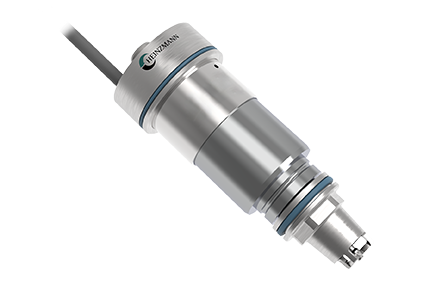

HEINZMANN Methanol Injector

(Source: © Heinzmann GmbH & Co. KG)

Methanol Injector with integrated flow limiter

(Source: © Heinzmann GmbH & Co. KG)

Methanol-powered tugboat of the Port of Antwerp

(Source: © 2024 Port of Antwerp)